Composite Disc Couplings: A Comprehensive Guide

1. Introduction

A composite disc coupling is a type of flexible coupling that is widely used in various industrial applications. It is designed to transmit torque while accommodating misalignment between shafts. This article aims to provide a detailed understanding of composite disc couplings and their key features.

2. Construction and Working Principle

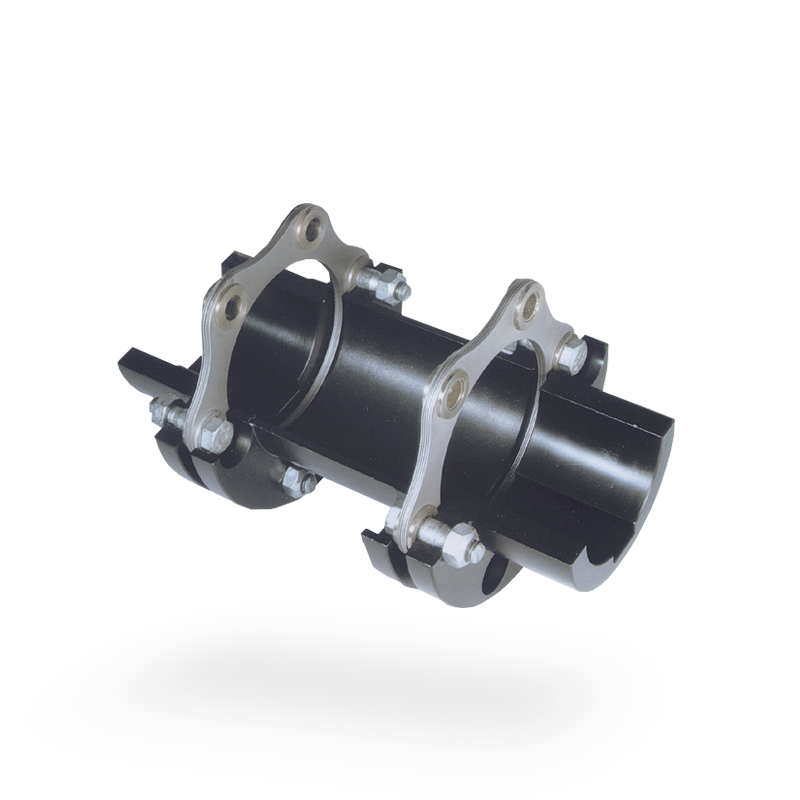

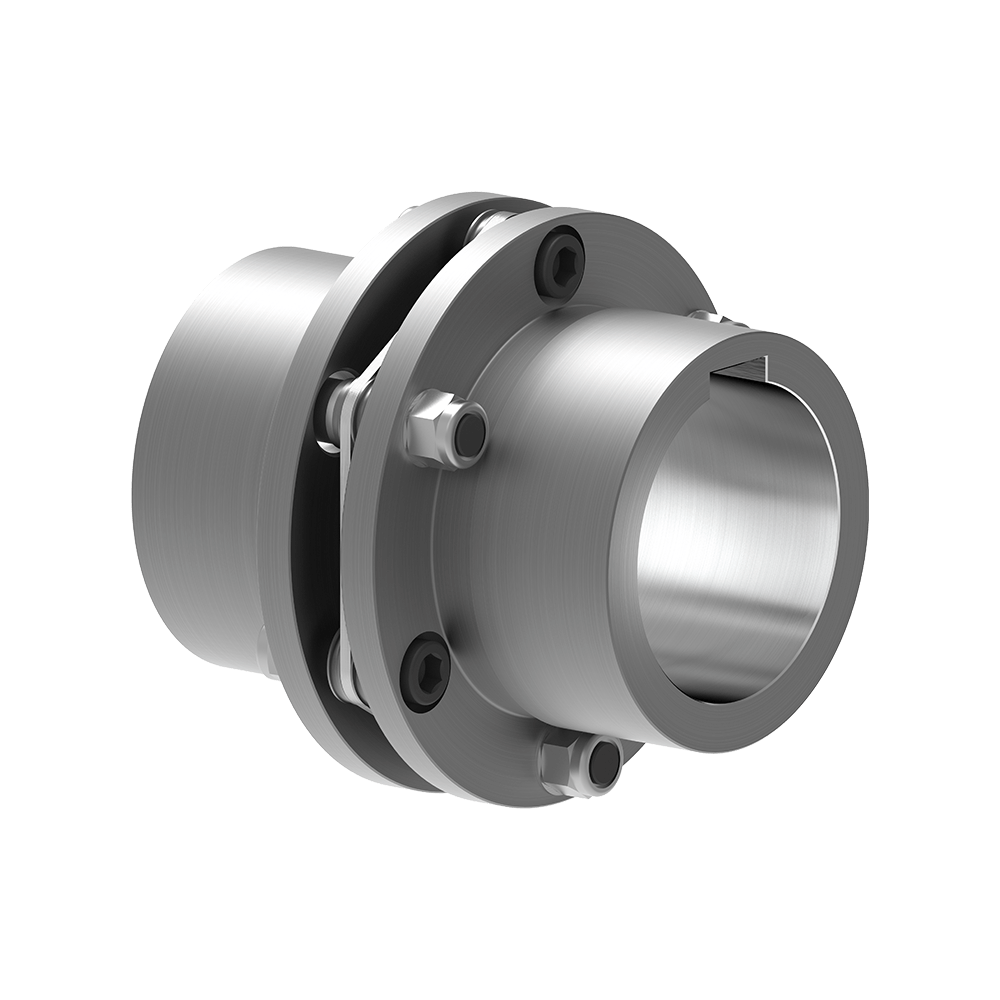

The composite disc coupling consists of two hubs, each attached to a shaft, and a series of flexible composite discs that connect the two hubs. These discs are made of high-strength materials such as composite resin, which ensures both flexibility and durability.

3. Advantages of Composite Disc Couplings

- High Torque Capacity: Composite disc couplings can transmit high levels of torque, making them suitable for heavy-duty applications.

- Excellent Misalignment Compensation: The flexible discs in the coupling can accommodate angular, parallel, and axial misalignment, ensuring smooth operation.

- Compact Design: Composite disc couplings have a compact and lightweight design, allowing for easy installation and space-saving.

- Low Maintenance: These couplings require minimal maintenance due to their robust construction and self-lubricating properties.

- High Precision: Composite disc couplings provide accurate torque transmission, making them suitable for precision machinery.

4. Selecting and Customizing a Suitable Disc Coupling

When choosing or customizing a disc coupling, several parameters and practical conditions need to be considered. These include:

- Shaft Size and Speed: The coupling should be designed to match the shaft diameter and rotational speed requirements.

- Misalignment Compensation: Determine the type and amount of misalignment that the coupling needs to accommodate.

- Operating Environment: Consider factors such as temperature, humidity, and corrosive conditions to select the appropriate materials for the coupling.

- Torsional Stiffness: Depending on the application, the coupling’s torsional stiffness should be carefully chosen to ensure optimal performance.

- Installation and Maintenance: Evaluate the ease of installation and any potential maintenance requirements for the selected coupling.

5. Does Disc Coupling Need Lubrication?

No, disc couplings are designed to be maintenance-free and do not require lubrication. This is due to the self-lubricating properties of the materials used in the construction of the coupling, ensuring smooth operation and extended service life.

What are Disc Couplings Used for?

Disc couplings find applications in a wide range of industries, including:

- Power Generation: Disc couplings are commonly used in power plants to connect various rotating equipment, such as turbines and generators.

- Petrochemical Industry: They are used in pumps, compressors, and other machinery involved in oil and gas processing.

- Steel and Metal Processing: Disc couplings are essential in rolling mills, where they transmit torque from motors to rollers.

- Machine Tools: They are utilized in CNC machines, lathes, and milling machines to ensure accurate torque transmission.

- Automotive Industry: Disc couplings are employed in automotive drivetrains for connecting the engine to the transmission system.

Overall, disc couplings offer reliable and efficient torque transmission for a wide range of industrial applications.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise specializing in the research, development, production, and international trade of couplings. With a focus on innovation and customer satisfaction, HZPT has become a leading global player in the coupling industry.

Our product range includes a variety of couplings such as drum couplings, pin-bush couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, membrane couplings, and tire couplings. We have a complete and scientific quality management system and our own technology development and testing department. HZPT holds certifications such as CQC, ISO, and CE.

By choosing HZPT, you can benefit from:

- High-Quality Products: We provide reliable and durable disc couplings that meet international standards.

- Customization Options: Our team can tailor the coupling to your specific requirements and applications.

- Technical Support: We offer excellent pre-sales and after-sales technical support to our customers.

- Global Presence: HZPT serves customers worldwide, ensuring reliable and timely delivery.

- Customer-Oriented Approach: We value our customers and strive to establish long-term partnerships based on trust and mutual growth.

Partner with HZPT for all your disc coupling needs and experience the difference in performance and reliability.