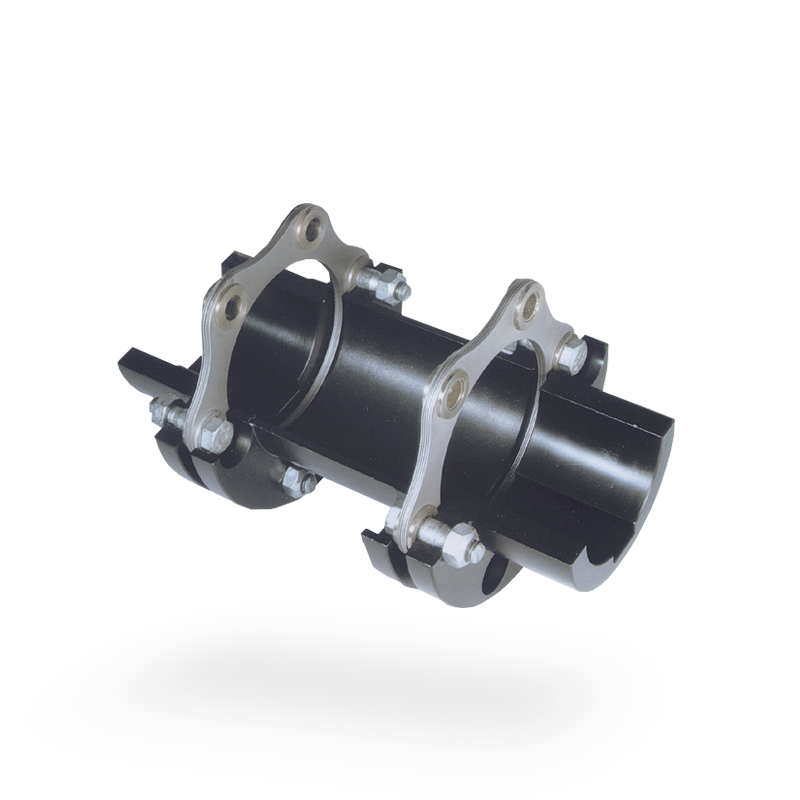

Coupling Disk

Introduction

A coupling disk, also known as a disc coupling, is a mechanical device used to connect two shafts for transmitting torque. It consists of two hubs or flanges with a flexible disc in between. The flexible disc compensates for misalignment between the shafts and helps to absorb shock and vibration, thereby protecting the connected equipment.

Types of Coupling Disks

1. Single Disc Coupling

2. Double Disc Coupling

3. Slit Disc Coupling

4. Diaphragm Disc Coupling

5. Gear Disc Coupling

6. Metallic Membrane Disc Coupling

7. Elastomeric Membrane Disc Coupling

8. Multi-Beam Disc Coupling

9. Bellows Disc Coupling

10. Torsional Disc Coupling

11. Oldham Disc Coupling

12. Cross-Slit Disc Coupling

13. Floating Disc Coupling

14. Axial Disc Coupling

15. High-Speed Disc Coupling

Exploration of Each Type

Single Disc Coupling

The single disc coupling consists of one flexible disc, which allows for angular misalignment and axial movement.

Double Disc Coupling

The double disc coupling employs two flexible discs connected by a spacer. It provides higher torque capacity and accommodates larger misalignments.

Slit Disc Coupling

The slit disc coupling has multiple slits on the flexible disc, which enhances flexibility and reduces reaction forces.

Diaphragm Disc Coupling

The diaphragm disc coupling utilizes a series of thin metallic diaphragms instead of a solid flexible disc. This design allows for high torque transmission and compensates for misalignment.

Gear Disc Coupling

The gear disc coupling features teeth on the disc surface, which provides a positive engagement and higher torque capacity.

Metallic Membrane Disc Coupling

The metallic membrane disc coupling uses a series of thin metallic membranes to transmit torque and accommodate misalignment.

Elastomeric Membrane Disc Coupling

The elastomeric membrane disc coupling incorporates elastomeric membranes to provide flexibility and damping characteristics.

Multi-Beam Disc Coupling

The multi-beam disc coupling consists of multiple beams arranged radially, allowing for high torque transmission and angular misalignment compensation.

Bellows Disc Coupling

The bellows disc coupling employs a bellows structure to compensate for axial, angular, and radial misalignments.

Torsional Disc Coupling

The torsional disc coupling is specifically designed to handle high torque and misalignment while maintaining stiffness and torsional rigidity.

Oldham Disc Coupling

The Oldham disc coupling uses two discs with slots and a central disc with a tongue, allowing for misalignment compensation.

Cross-Slit Disc Coupling

The cross-slit disc coupling has diagonal slits on the disc, enhancing flexibility while maintaining high torsional stiffness.

Floating Disc Coupling

The floating disc coupling consists of two discs connected by pins, allowing for misalignment compensation in multiple directions.

Axial Disc Coupling

The axial disc coupling is designed to transmit torque while accommodating axial misalignment between the shafts.

High-Speed Disc Coupling

The high-speed disc coupling is specifically engineered for high-speed applications, ensuring reliable torque transmission and balance.

What are Disc Couplings Used For?

Disc couplings are widely used in various industries and applications, including:

1. Power transmission systems

2. Pumping systems

3. Compressors

4. Generators

5. Machine tools

6. Paper mills

7. Steel mills

8. Petrochemical plants

9. Mining equipment

10. Marine propulsion systems

Disc couplings are essential for transmitting torque between shafts while compensating for misalignment and reducing shock and vibration. They ensure smooth operation, increase equipment lifespan, and minimize downtime.

How to Choose or Customize a Suitable Disc Coupling?

When selecting or customizing a disc coupling, it is crucial to consider the following parameters and real-world conditions:

1. Torque requirements: Determine the maximum torque that the coupling needs to transmit.

2. Speed range: Consider the operating speed and ensure the selected coupling can handle the required RPM.

3. Misalignment compensation: Evaluate the expected misalignment between the connected shafts and select a coupling that can accommodate it.

4. Space limitations: Consider the available space for installation and choose a compact coupling design if necessary.

5. Operating environment: Assess the temperature, humidity, and presence of corrosive substances to select a suitable material and coating.

It is important to consult with coupling manufacturers or experts to ensure the proper selection or customization of a disc coupling based on the specific requirements of the application.

Does Disc Coupling Need Lubrication?

Disc couplings generally do not require lubrication. They operate with dry friction between the metal surfaces of the discs, eliminating the need for regular lubrication maintenance.

However, in some cases, particularly in high-speed or high-temperature applications, lubrication may be recommended to reduce wear and enhance performance. It is advisable to consult the coupling manufacturer for specific lubrication requirements based on the operating conditions.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise specializing in the research, development, production, and international trade of coupling products. We adhere to the core values of honesty and integrity, unity, progress, and innovation.

Our company combines high-tech development, international trade, industrial investment, and domestic and foreign networks, focusing on the research and innovation of coupling products. We have a wide range of coupling products, including drum couplings, pin-bushing couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, membrane couplings, tire couplings, and more.

With a complete and scientific quality management system, as well as our own technical development and testing department, we have obtained certifications such as CQC, ISO, and CE. We provide excellent sales service and technical support to our customers. We have served more than a hundred cooperating companies and strive to cooperate sincerely with customers for mutual development.

Our company specializes in the production and sale of disc couplings. We offer high-quality products with the following advantages:

1. High torque transmission capacity: Our disc couplings are designed to handle various torque requirements, ensuring reliable power transmission.

2. Misalignment compensation: The flexibility of our disc couplings allows for the compensation of angular, axial, and radial misalignments, reducing stress on connected equipment.

3. Shock and vibration absorption: The design of our disc couplings helps to absorb shock and vibration, protecting the connected machinery and increasing its operational lifespan.

4. Wide range of applications: Our disc couplings are suitable for various industries, including power transmission, pumping systems, marine propulsion, and more.

5. Customization options: We offer customization services to meet specific customer requirements, providing tailored solutions for unique applications.

With our extensive experience, technical expertise, and commitment to customer satisfaction, we are confident in delivering top-quality disc couplings that meet the highest standards of performance and reliability.

For more information about our disc coupling products, please visit our website or contact us directly. We look forward to the opportunity to serve you and establish a fruitful partnership.