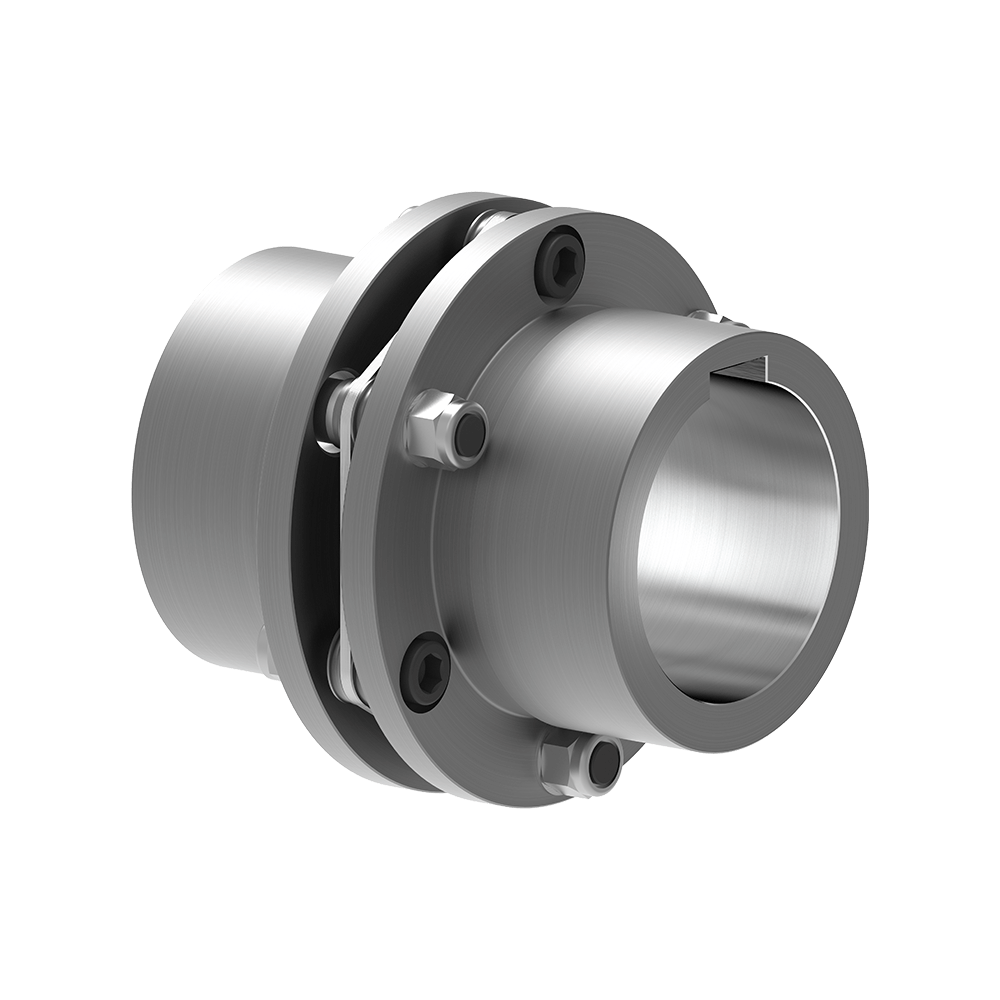

Disc Coupling for Laser Cutting Machines

Introduction

Disc coupling is a crucial component in laser cutting machines, providing high precision and efficiency in power transmission. This article will explore the various aspects of disc couplings and their importance in laser cutting technology.

The Function of Disc Coupling

Disc couplings play a vital role in laser cutting machines by transmitting torque and compensating for misalignments between the motor and the laser head. They enable smooth power transmission, reducing vibration and ensuring precise cutting operations.

Advantages of Disc Coupling

1. High Torque Capacity: Disc couplings have excellent torque transmission capabilities, allowing them to handle the high power requirements of laser cutting machines efficiently.

2. Flexibility: These couplings can compensate for axial, angular, and parallel misalignments, ensuring optimal performance and extending the lifespan of the laser cutting system.

3. Zero Backlash: The design of disc couplings offers zero backlash, meaning there is no delay or play in power transmission, resulting in accurate and reliable laser cutting operations.

4. Maintenance-Free: Disc couplings require minimal maintenance due to their robust construction and high-quality materials. This reduces downtime and increases overall productivity.

5. Compact Design: Disc couplings have a compact and lightweight structure, making them ideal for laser cutting machines, where space is often limited.

Selecting or Customizing the Right Disc Coupling

When choosing or customizing a disc coupling for laser cutting machines, several parameters and practical conditions need consideration. Here are the key factors to consider:

1. Operating Torque: Calculate and determine the maximum torque required for the laser cutting machine to ensure the selected disc coupling can handle the load.

2. Misalignment Compensation: Evaluate the allowable misalignments between the motor and laser head and choose a disc coupling with the appropriate angular, axial, and parallel misalignment capabilities.

3. Speed and Temperature: Consider the rotational speed and operating temperature of the laser cutting machine and select a disc coupling that can withstand these conditions without compromising performance.

4. Material Selection: Choose the right material for the disc coupling based on factors such as corrosion resistance, durability, and compatibility with the laser cutting environment.

5. Cost-Effectiveness: Assess the overall cost-effectiveness of the disc coupling, considering its performance, maintenance requirements, and lifespan in relation to the laser cutting machine’s budget and operational needs.

Does Disc Coupling Need Lubrication?

Unlike many other coupling types, disc couplings are typically designed to operate without the need for lubrication. They utilize dry frictional force between the disc packs, eliminating the need for lubricating oils or greases. This feature reduces maintenance efforts and makes disc couplings a cleaner and more efficient choice for laser cutting machines.

About HZPT

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise integrating research, development, production, and international trade. We specialize in the production of various disc couplings and other coupling products.

Our company adheres to the core values of integrity, unity, progress, and innovation. With a focus on high-tech development, international trade, industrial investment, and global network, we aim to become an internationally influential group.

With a complete and scientific quality management system, as well as our own technical development and testing department, we have obtained certifications such as CQC, ISO, and CE. We provide excellent sales and technical support services to our customers.

Why Choose Our Disc Coupling?

1. Superior Quality: Our disc couplings are manufactured using high-quality materials, ensuring durability, reliability, and long service life.

2. Precision Engineering: Each disc coupling is designed with precision engineering techniques to provide accurate and efficient power transmission, contributing to the optimal performance of laser cutting machines.

3. Customization Options: We offer customization services to meet specific requirements, allowing customers to choose the appropriate size, material, and design for their laser cutting machines.

4. Technical Expertise: With our dedicated technical development and testing department, we have the expertise to provide comprehensive support and guidance in selecting the right disc coupling for each application.

5. Competitive Pricing: We strive to offer competitive prices without compromising on quality, making our disc couplings a cost-effective choice for customers.

In conclusion, HZPT is a professional manufacturer and supplier of disc couplings. Our high-quality products, technical expertise, and customer-oriented approach make us an ideal partner for your laser cutting machine needs. Contact us now to start a fruitful collaboration!

What are disc couplings used for?