Disc Coupling for PCB Manufacturing Machinery

Introduction

Disc coupling is a crucial component used in PCB manufacturing machinery. It plays a significant role in connecting the motor and the machinery, ensuring efficient power transmission and reducing the risk of misalignment. In this article, we will explore the various aspects of disc coupling and its importance in the PCB manufacturing industry.

1. Understanding Disc Coupling

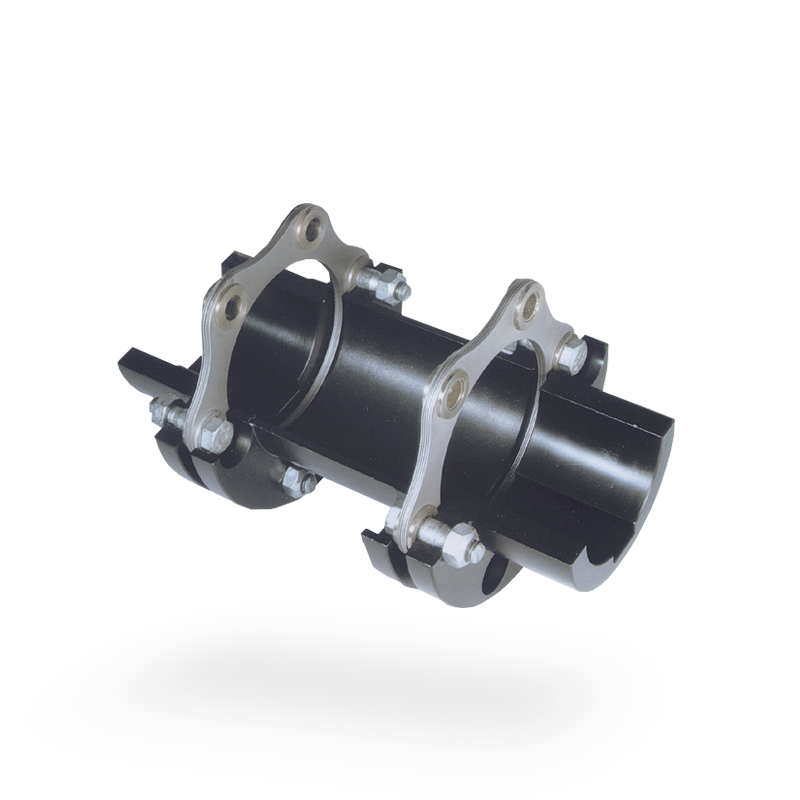

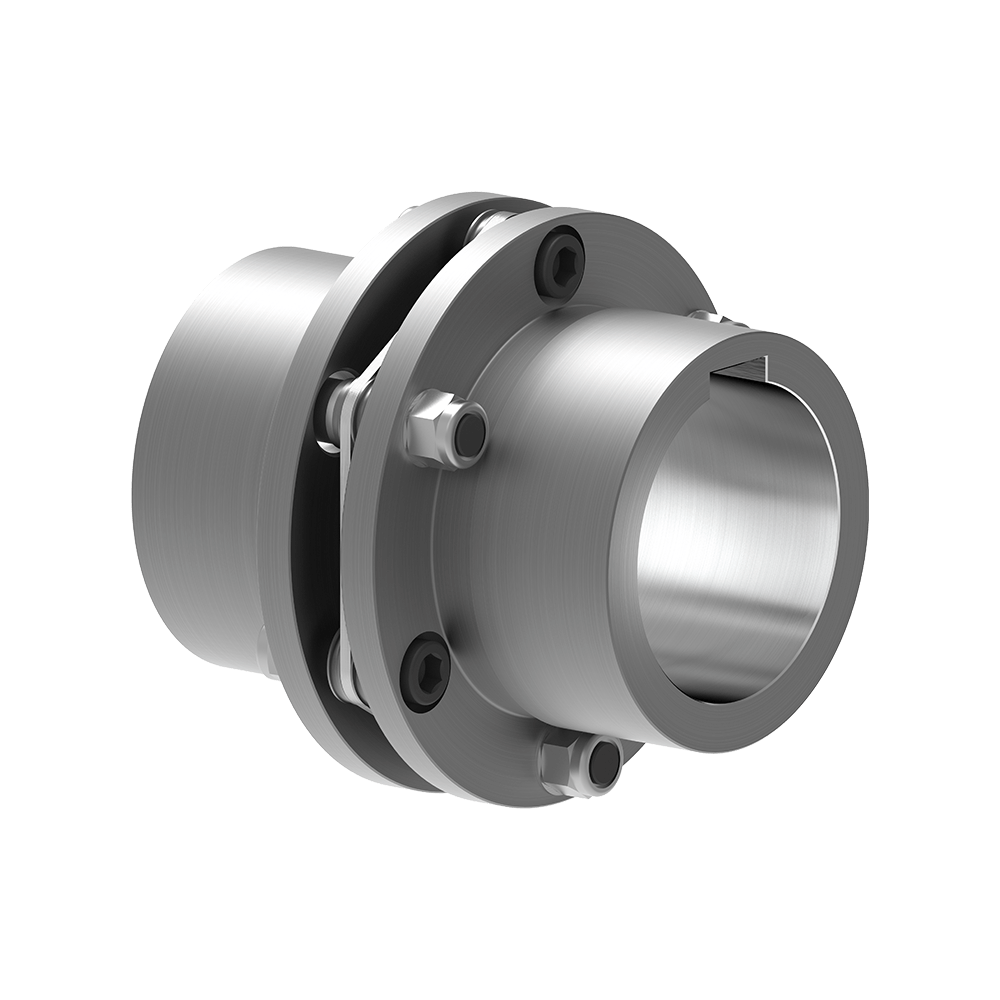

Disc coupling is a flexible coupling that consists of two flanged hubs and a series of thin metal discs. These discs are arranged in a stack and are alternately bolted between the hubs. The design allows for angular, parallel, and axial misalignment while transmitting torque between the motor and the machinery. The disc coupling’s unique construction offers high torsional stiffness, excellent misalignment capabilities, and a compact size.

2. Advantages of Disc Coupling

– High Torque Transmission: Disc couplings can transmit high torque without sacrificing performance or introducing excessive backlash.

– Misalignment Compensation: The flexible nature of disc couplings allows for angular, parallel, and axial misalignment compensation, reducing stress on the machinery and increasing its lifespan.

– High Torsional Stiffness: Disc couplings offer high torsional stiffness, ensuring accurate and reliable power transmission.

– Maintenance-Free Operation: Due to their robust design and use of high-quality materials, disc couplings require minimal maintenance, resulting in increased productivity and reduced downtime.

– Compact Design: Disc couplings have a compact size, making them suitable for space-constrained PCB manufacturing machinery.

3. How to Select or Customize the Right Disc Coupling

When selecting or customizing a disc coupling, several parameters and practical conditions need to be considered. These include:

– Torque Capacity: Determine the required torque capacity based on the machinery’s power requirements and operating conditions.

– Misalignment Compensation: Evaluate the degree and type of misalignment that the coupling needs to accommodate, such as angular, parallel, or axial misalignment.

– Operating Speed: Consider the machinery’s operating speed to ensure the disc coupling can withstand the rotational forces without compromising performance.

– Environmental Conditions: Assess the temperature, humidity, and other environmental factors to choose materials that can withstand the specific conditions.

– Installation Space: Measure the available space for the coupling in the machinery to select the appropriate size and compact design.

4. Does Disc Coupling Need Lubrication?

Unlike many other types of couplings, disc couplings are typically designed to operate in a dry condition and do not require lubrication. The disc coupling’s material and design minimize friction and wear, resulting in maintenance-free operation.

What are Disc Couplings Used For?

Disc couplings are widely used in various industries, including PCB manufacturing. They are primarily used for:

– Connecting the motor and machinery in PCB manufacturing equipment.

– Transmitting torque between the motor and machinery while compensating for misalignment.

– Reducing stress on the machinery components and increasing their lifespan.

Choosing and Customizing Disc Couplings

To select or customize the right disc coupling, consider the following factors:

1. Torque Capacity: Evaluate the machinery’s power requirements to determine the appropriate torque capacity.

2. Misalignment Compensation: Identify the type and degree of misalignment the coupling needs to accommodate.

3. Operating Speed: Consider the machinery’s rotational speed and choose a disc coupling that can handle it effectively.

4. Environmental Conditions: Assess the environmental factors like temperature and humidity to select suitable materials.

5. Installation Space: Measure the available space in the machinery to ensure the chosen disc coupling fits properly.

About HZPT

HZPT is a modern enterprise located in Hangzhou, Zhejiang Province. We specialize in the research, development, production, and international trade of disc couplings and other coupling products. With our core values of integrity, unity, progress, and innovation, we aim to become a globally influential international group.

Our extensive product range includes drum couplings, pin-bushing couplings, serpentine spring couplings, universal couplings, star couplings, expanding couplings, membrane couplings, and tire couplings. We have a complete and scientific quality management system and our own technology development and testing department. Our company holds certifications such as CQC, ISO, and CE, ensuring high-quality products and services for our customers.

Why Choose HZPT Disc Couplings?

1. Superior Torque Transmission: Our disc couplings offer exceptional torque transmission capabilities, ensuring efficient power transfer.

2. Precise Misalignment Compensation: The flexible design of our disc couplings allows for precise compensation of angular, parallel, and axial misalignment, reducing stress on machinery components.

3. Robust and Reliable: Our disc couplings are constructed with high-quality materials, providing durability and reliability in demanding industrial environments.

4. Minimal Maintenance: With their maintenance-free operation, our disc couplings help minimize downtime and increase productivity.

5. Customization Options: We offer a range of customization options to tailor our disc couplings to specific machinery requirements, ensuring optimal performance.

In conclusion, HZPT is your trusted partner for all your disc coupling needs. With our high-quality products, technical expertise, and customer-oriented approach, we are committed to providing excellent sales support and technical assistance. Join us in our journey towards mutual growth and success.