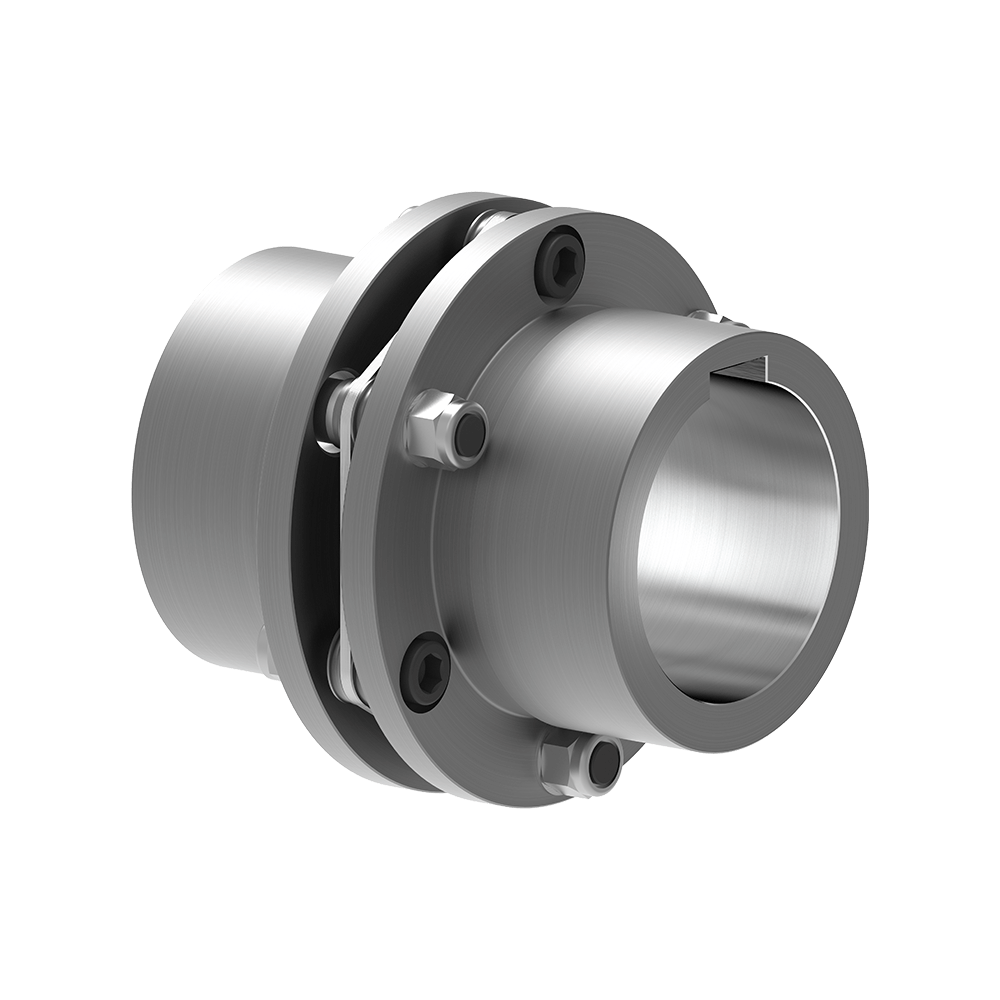

Disc Coupling for Testing and Inspection Machines

Introduction

Disc couplings are crucial components used in testing and inspection machines. These couplings provide a reliable connection between various equipment components, ensuring efficient and accurate operation. In this article, we will explore the features and benefits of disc couplings for testing and inspection machines.

1. Understanding Disc Couplings

Disc couplings, also known as diaphragm couplings, are flexible couplings designed to transmit torque between two shafts while compensating for misalignment. They consist of a series of thin metal discs that are bolted together to form a pack. The diaphragm shape of the discs allows for angular, axial, and parallel misalignment while maintaining high torsional stiffness.

2. Advantages of Disc Couplings

Disc couplings offer several advantages that make them ideal for testing and inspection machines:

- High Torque Capacity: Disc couplings can handle high torque loads, ensuring reliable performance in demanding applications.

- Flexibility: The design of disc couplings allows for misalignment compensation, reducing stress on connected equipment and increasing overall system lifespan.

- Zero Backlash: The bolted design of disc couplings eliminates backlash, enabling precise and accurate positioning in testing and inspection machines.

- High Torsional Stiffness: Disc couplings provide excellent torsional stiffness, minimizing torsional vibrations and ensuring precise motion control.

- Durable and Maintenance-Free: Disc couplings are made of high-quality materials, offering long-term reliability and eliminating the need for frequent maintenance.

3. Disc Coupling Selection and Customization

When selecting or customizing a disc coupling for testing and inspection machines, it is essential to consider various parameters and practical conditions:

- Operating Torque: Determine the maximum torque the disc coupling needs to transmit to ensure proper function and avoid overload.

- Shaft Misalignment: Assess the anticipated misalignment in terms of angular, axial, and parallel misalignment to choose a disc coupling that can accommodate these misalignments effectively.

- Speed and RPM: Consider the rotational speed and RPM requirements of the testing and inspection machines to select a disc coupling that can handle the desired operating conditions.

- Environmental Factors: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals or contaminants, to choose a disc coupling with suitable corrosion resistance and durability.

- Installation Space: Take into account the available space for the disc coupling installation, ensuring it fits within the machine’s design constraints.

4. Does Disc Coupling Need Lubrication?

No, disc couplings are typically designed to be lubrication-free. The metal discs in disc couplings are often coated with materials that provide self-lubrication properties. This eliminates the need for additional lubrication, reducing maintenance requirements and minimizing the risk of contamination in testing and inspection machines.

Conclusion

Disc couplings are indispensable components for testing and inspection machines, offering versatility, reliability, and precise torque transmission. At HZPT, located in Hangzhou, Zhejiang Province, we specialize in the production and sale of disc couplings. With our commitment to integrity and customer satisfaction, we have become a leading provider in the industry. Our disc couplings are designed with advanced technology, ensuring optimal performance and durability. Choose HZPT for your disc coupling needs and experience the benefits of our high-quality products.

Why Choose HZPT Disc Couplings?

- Advanced Manufacturing: Our disc couplings are manufactured using state-of-the-art technology, ensuring superior quality and precision.

- Extensive Product Range: We offer a wide range of disc couplings, including drum-shaped, spring pin, serpentine spring, universal, star-shaped, expansion, membrane, and tire couplings.

- Quality Assurance: With a comprehensive quality management system and certifications such as CQC, ISO, and CE, we guarantee the reliability and performance of our disc couplings.

- Technical Expertise: Our dedicated team of engineers and technicians ensures continuous innovation and provides excellent technical support to customers.

- Global Reach: We have established a strong presence in Asia, Europe, Africa, and North America, aiming to become a globally influential international group.

Choose HZPT disc couplings for your testing and inspection machines and benefit from our exceptional products and company advantages.

Contact Us

Please feel free to contact us for further information or inquiries:

Company: HZPT

Location: Hangzhou, Zhejiang Province, China

Business Philosophy: Integrity, Unity, Progress, Innovation

Contact: Phone: +86-123456789

Email: [email protected]