Disc coupling for Electronics Production Lines

Introduction

Disc coupling is a vital component in electronics production lines, providing efficient and reliable power transmission. This article explores the various aspects of disc couplings and their significance in the electronics industry.

1. Overview of Disc Coupling

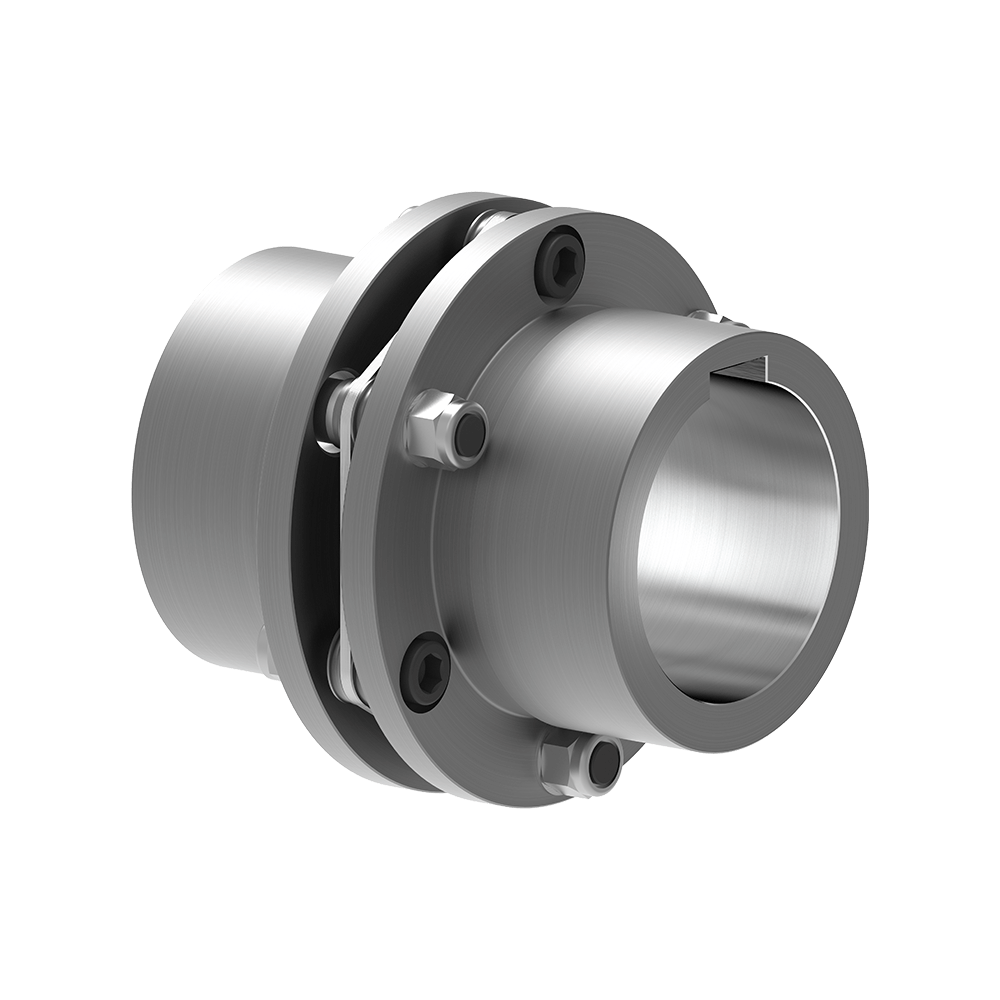

Disc coupling, also known as a disk coupling, is a type of flexible coupling used in electronics production lines to connect rotating equipment. It consists of two metal hubs with a series of thin metal discs, which are bolted together to form a flexible and torsionally stiff connection.

2. Advantages of Disc Couplings

Disc couplings offer several advantages over other types of couplings:

- High Torque Capacity: Disc couplings can transmit high torque loads, making them suitable for demanding applications in electronics production.

- Compensation for Misalignment: They can accommodate misalignment between shafts, reducing stress on the connected equipment.

- Torsional Stiffness: Disc couplings provide excellent torsional stiffness, ensuring accurate and precise power transmission.

- Zero Backlash: They have minimal or zero backlash, resulting in smoother operation and improved system performance.

- Compact Design: Disc couplings are compact and lightweight, making them ideal for space-constrained electronics production lines.

3. Selecting and Customizing Disc Couplings

When selecting or customizing disc couplings for specific applications, certain parameters and conditions need to be considered:

- Shaft Diameter: The disc coupling should be compatible with the shaft diameter of the connected equipment.

- Torque Requirements: The coupling must be able to handle the required torque load without exceeding its capacity.

- Operating Speed: The disc coupling’s maximum rated speed should match or exceed the operating speed of the equipment.

- Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals or contaminants.

- Installation Space: Ensure that the dimensions of the disc coupling fit within the available installation space.

4. Lubrication Requirements for Disc Couplings

Disc couplings generally do not require lubrication. The design of the coupling allows for dry operation, reducing maintenance and eliminating the risk of contamination or leakage.

What are disc couplings used for?

Disc couplings are widely used in electronics production lines for various applications, including:

- Robotics and Automation Systems

- Precision Motion Control

- Conveyor Systems

- Packaging Equipment

- Printing and Labeling Machines

Why Choose Our Disc Couplings?

At HZPT, we specialize in the production and sale of disc couplings. Our products offer the following advantages:

- Durable and Reliable: Our disc couplings are made from high-quality materials, ensuring long-lasting performance and reliability.

- Wide Range of Sizes: We offer a wide range of disc coupling sizes to accommodate various shaft diameters and torque requirements.

- Customization Options: We can customize disc couplings to meet specific application needs, providing tailored solutions for our customers.

- Expert Technical Support: Our team of experts is available to assist customers in selecting the right disc coupling for their application and providing technical support.

- Global Presence: We have a global presence and serve customers worldwide, ensuring timely delivery and exceptional customer service.