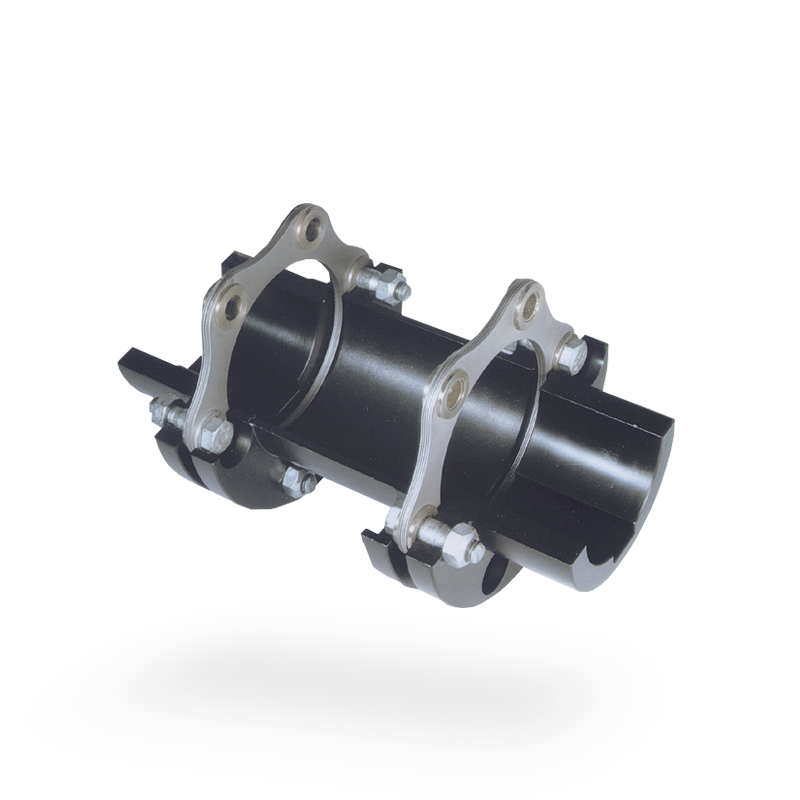

Disc Coupling for Plasma Cutting Machines

Introduction

Disc coupling is a crucial component in plasma cutting machines, providing a reliable connection between the motor and the cutting tool. This article will explore the various aspects of disc couplings, including their function, selection criteria, lubrication requirements, and more.

Function of Disc Coupling

Disc couplings play a vital role in transmitting torque and compensating for misalignment in plasma cutting machines. They provide a flexible connection between the motor and the cutting tool, allowing for smooth and efficient power transmission.

Choosing and Customizing Disc Couplings

When selecting or customizing a disc coupling, several parameters and real-world conditions need to be considered. Here are some key factors to keep in mind:

1. Torque Capacity

The disc coupling should be able to handle the maximum torque generated by the plasma cutting machine. It is essential to consider the motor power, cutting tool size, and material thickness to determine the appropriate torque capacity.

2. Misalignment Compensation

Disc couplings are designed to compensate for both angular and parallel misalignment. It is crucial to ensure that the selected coupling can accommodate the anticipated misalignment in the plasma cutting machine.

3. Operating Speed

The operating speed of the plasma cutting machine influences the selection of the disc coupling. Higher speeds may require specialized couplings with enhanced balance capabilities to minimize vibrations and ensure smooth operation.

4. Environmental Factors

The operating environment of the plasma cutting machine, including temperature, humidity, and exposure to dust or chemicals, should be taken into account. Choosing a disc coupling with appropriate material coating or corrosion resistance can prolong its lifespan.

5. Maintenance and Serviceability

Consider the ease of maintenance and serviceability when selecting a disc coupling. Features such as easy disassembly and reassembly can significantly reduce downtime and maintenance costs.

Does Disc Coupling Need Lubrication?

Yes, disc couplings generally require lubrication to ensure smooth operation and reduce wear. Lubrication helps to minimize friction and protect the disc coupling’s components from excessive heat and premature failure. It is essential to follow the manufacturer’s recommendations regarding lubrication intervals and types of lubricants to maintain optimal performance.

What are Disc Couplings Used For?

Disc couplings are widely used in various industrial applications, including:

– Plasma cutting machines

– Machine tools

– Printing presses

– Packaging equipment

– Material handling systems

Disc couplings offer several advantages over other types of couplings, including:

1. High Torque Transmission

Disc couplings can handle high torque loads, making them suitable for demanding applications such as plasma cutting machines.

2. Compact Design

The compact design of disc couplings allows for easy installation in space-constrained environments, ensuring efficient use of available space.

3. Misalignment Compensation

Disc couplings can accommodate both angular and parallel misalignment, providing flexibility and reducing stress on connected equipment.

4. High Speed Capability

They are capable of operating at high speeds without compromising performance, making them suitable for applications with rapid rotational requirements.

5. Maintenance-Free Operation

With proper lubrication and maintenance, disc couplings can provide extended service life and reliable operation without the need for frequent maintenance.

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise specializing in the development, production, and international trade of various couplings. With a focus on innovation and customer satisfaction, HZPT aims to be a globally influential international group.

Our company specializes in the production and sale of disc couplings, including drum couplings, pin-bushing couplings, elastomeric couplings, universal couplings, star couplings, expansion couplings, membrane couplings, and tire couplings. We have a complete and scientific quality management system, as well as our own technical development and testing department. Our certifications include CQC, ISO, and CE.

Reasons to choose our disc couplings:

1. High torque capacity to meet demanding plasma cutting machine requirements.

2. Excellent misalignment compensation for smooth and efficient power transmission.

3. Designed for high-speed applications, minimizing vibrations and ensuring precision.

4. Corrosion-resistant materials for durability in diverse operating environments.

5. Easy maintenance and serviceability, reducing downtime and maintenance costs.

Contact us today to explore our range of disc couplings and experience our exceptional sales service and technical support. We look forward to partnering with you for mutual growth and success.