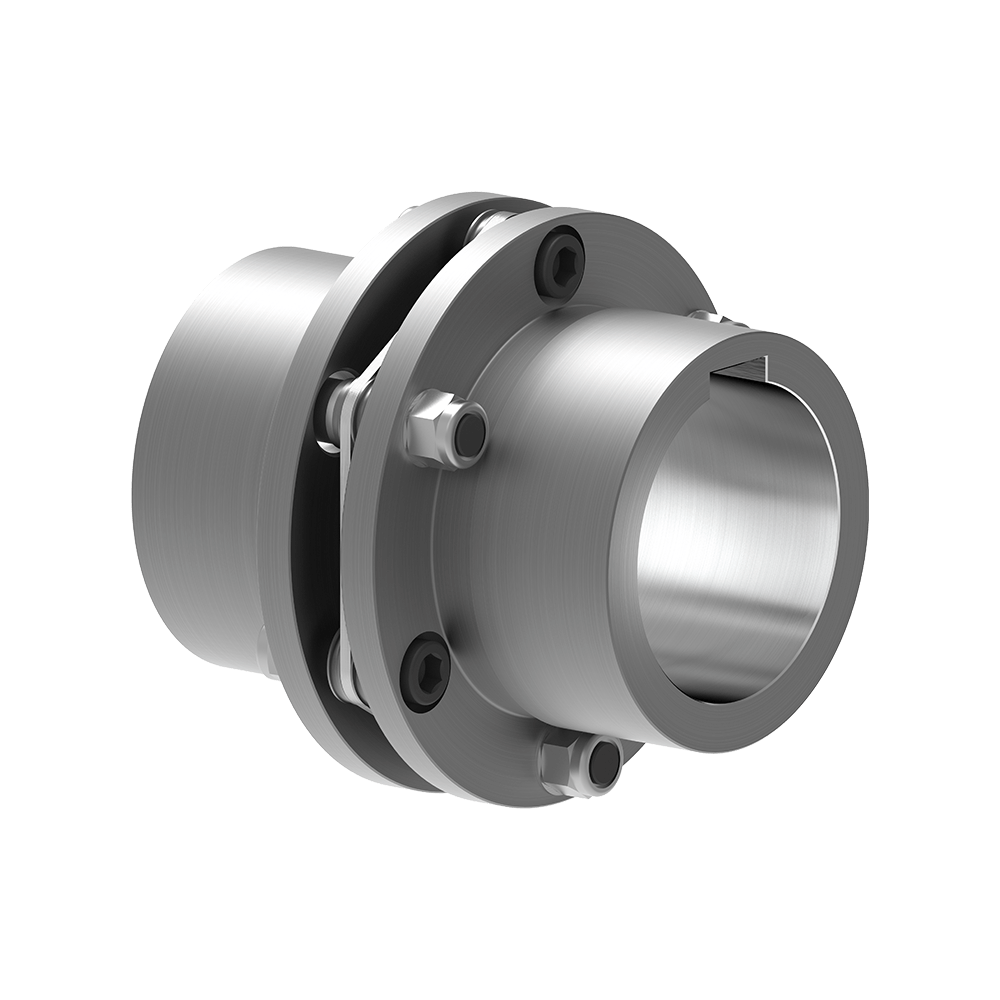

dodge disc coupling

Introduction

The dodge disc coupling is a type of flexible coupling used in various industrial applications. It is designed to transmit torque between two shafts while accommodating misalignment and damping vibrations. This article will explore the features, applications, and advantages of dodge disc couplings.

1. What is a disc coupling?

A disc coupling consists of a series of thin metal discs that are bolted together. The discs are alternately bolted to each shaft, creating a parallel stack. These discs flex under torque, allowing for misalignment compensation and damping of torsional vibrations.

2. Advantages of dodge disc couplings

– High torque capacity: Dodge disc couplings can transmit high levels of torque, making them suitable for heavy-duty applications.

– Misalignment compensation: The flexible design of disc couplings allows for angular, parallel, and axial misalignment between shafts.

– Vibration damping: The metal discs in dodge disc couplings absorb and dissipate torsional vibrations, reducing stress on connected equipment.

– Maintenance-free operation: Disc couplings do not require lubrication, resulting in cost savings and simplified maintenance.

– High-speed capability: Dodge disc couplings can operate at high speeds without compromising performance or safety.

3. Applications of dodge disc couplings

Dodge disc couplings find application in various industries, including:

– Power generation: They are used in turbines, generators, and pumps.

– Oil and gas: Disc couplings are employed in compressors, pumps, and drilling equipment.

– Mining: They are utilized in conveyors, crushers, and mills.

– Steel and metal processing: Disc couplings are used in rolling mills, extruders, and presses.

– Marine: They find application in propulsion systems, thrusters, and winches.

4. How to choose or customize a suitable disc coupling?

To select or customize a suitable disc coupling, the following parameters and practical conditions should be considered:

– Torque requirements: Determine the torque capacity needed for your specific application.

– Shaft misalignment: Assess the degree of angular, parallel, and axial misalignment.

– Speed and power transmission capacity: Consider the operating speed and power requirements.

– Environmental factors: Evaluate temperature, humidity, and exposure to chemicals or corrosive substances.

– Space limitations: Consider the available space for installation and any design constraints.

5. Does disc coupling need lubrication?

No, disc couplings do not require lubrication. The metal discs provide flexibility and allow for smooth torque transmission without the need for additional lubrication. This eliminates the maintenance tasks associated with lubrication, reducing downtime and costs.

Conclusion

In conclusion, dodge disc couplings are versatile and reliable components used in various industrial applications. With their ability to accommodate misalignment, dampen vibrations, and transmit high torque, they offer numerous advantages. Whether in power generation, oil and gas, mining, steel processing, or marine industries, dodge disc couplings provide efficient and maintenance-free operation. For all your coupling needs, consider HZPT, a leading manufacturer and supplier of disc couplings.

What are disc couplings used for?

Disc couplings are used to transmit torque between two shafts while accommodating misalignment and damping vibrations. They are commonly employed in industries such as power generation, oil and gas, mining, steel processing, and marine applications. The flexible design and high torque capacity of disc couplings make them suitable for heavy-duty operations.

How to choose or customize a suitable disc coupling?

When selecting or customizing a disc coupling, several parameters and practical conditions should be considered:

– Torque requirements: Determine the torque capacity needed for your specific application.

– Shaft misalignment: Assess the degree of angular, parallel, and axial misalignment.

– Speed and power transmission capacity: Consider the operating speed and power requirements.

– Environmental factors: Evaluate temperature, humidity, and exposure to chemicals or corrosive substances.

– Space limitations: Consider the available space for installation and any design constraints.

Does disc coupling need lubrication?

No, disc couplings do not require lubrication. The metal discs provide flexibility and allow for smooth torque transmission without the need for additional lubrication. This eliminates the maintenance tasks associated with lubrication, reducing downtime and costs.

About HZPT

HZPT is a modern enterprise located in Hangzhou, Zhejiang Province. We specialize in the research, development, production, and international trade of coupling products. Committed to our core values of integrity, unity, progress, and innovation, we aim to become a globally influential international group.

Our company offers a wide range of coupling products, including drum couplings, pin-bushing couplings, serpentine spring couplings, universal couplings, star couplings, shrink disc couplings, membrane couplings, and tire couplings. With a complete and scientific quality management system, as well as our own technical development and testing department, we have obtained certifications such as CQC, ISO, and CE. We pride ourselves on providing excellent sales service and technical support to our customers.

By adhering to the principles of “customer-oriented” and “people-oriented,” we have established fruitful partnerships with over a hundred cooperative enterprises. We invite you to explore the advantages of our disc couplings and join us in our journey of mutual development and success.