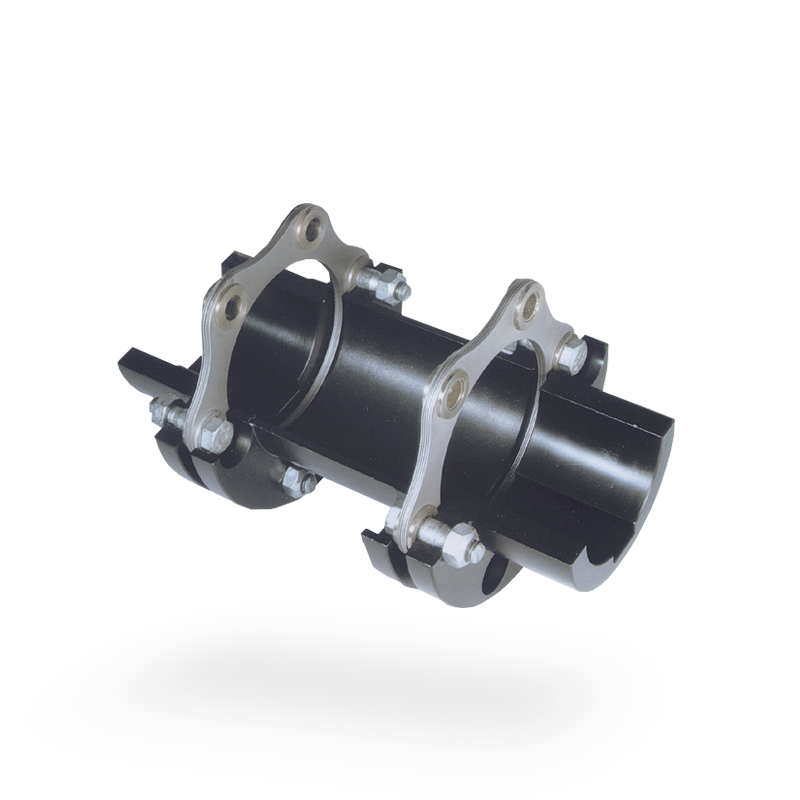

lamidisc coupling

Introduction

The lamidisc coupling is a highly versatile and efficient coupling device used in various industrial applications. Its unique design and construction make it suitable for transmitting torque and accommodating misalignment between shafts. In this article, we will explore the key features and advantages of the lamidisc coupling, as well as its applications and selection criteria.

1. What is a lamidisc coupling?

The lamidisc coupling is a type of flexible coupling that consists of multiple metal discs stacked together. These discs are specially designed to provide flexibility and allow for angular, parallel, and axial misalignments between the connected shafts. The lamidisc coupling is known for its high torsional stiffness, excellent torque transmission capabilities, and fatigue resistance.

2. Advantages of lamidisc coupling

– High torque transmission capacity: The lamidisc coupling can transmit high torque loads, making it suitable for demanding industrial applications.

– Excellent misalignment accommodation: With its flexible disc design, the lamidisc coupling can accommodate angular, parallel, and axial misalignments, reducing stress on the connected equipment.

– Compact and lightweight: The lamidisc coupling has a compact and lightweight construction, minimizing space requirements and allowing for easy installation.

– High torsional stiffness: The lamidisc coupling offers high torsional stiffness, ensuring precise and efficient torque transmission.

– Maintenance-free operation: Thanks to its durable and reliable design, the lamidisc coupling requires minimal maintenance, reducing downtime and operational costs.

3. Applications of lamidisc coupling

The lamidisc coupling finds applications in various industries, including:

– Power generation: The lamidisc coupling is used in turbines, generators, and other power generation equipment to transmit torque and accommodate misalignments.

– Petrochemical industry: It is employed in pumps, compressors, and other equipment used in the petrochemical industry to ensure efficient and reliable operation.

– Mining and material handling: The lamidisc coupling is utilized in conveyor systems, crushers, and other mining and material handling equipment for reliable torque transmission.

– Marine industry: It is used in marine propulsion systems, thrusters, and other marine equipment to transmit torque and compensate for misalignments.

– Steel industry: The lamidisc coupling is employed in rolling mills, steel processing equipment, and other applications in the steel industry that require high torque transmission and misalignment compensation.

4. Selecting and customizing a lamidisc coupling

When selecting or customizing a lamidisc coupling, several factors should be considered:

– Torque requirements: Determine the maximum and continuous torque loads the coupling will need to transmit.

– Speed and misalignment: Consider the rotational speed and the expected misalignments between the connected shafts.

– Environmental conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals or abrasive substances.

– Space constraints: Take into account any space limitations that may affect the size and configuration of the coupling.

– Customization options: Discuss with a coupling manufacturer the possibility of customizing the lamidisc coupling to meet specific application requirements.

Does a lamidisc coupling need lubrication?

No, the lamidisc coupling does not require lubrication. The metal discs used in the coupling are designed to operate dry, eliminating the need for regular lubrication and reducing maintenance requirements.

After discussing the features and applications of the lamidisc coupling, let’s take a closer look at HZPT, a leading manufacturer of high-quality coupling products.

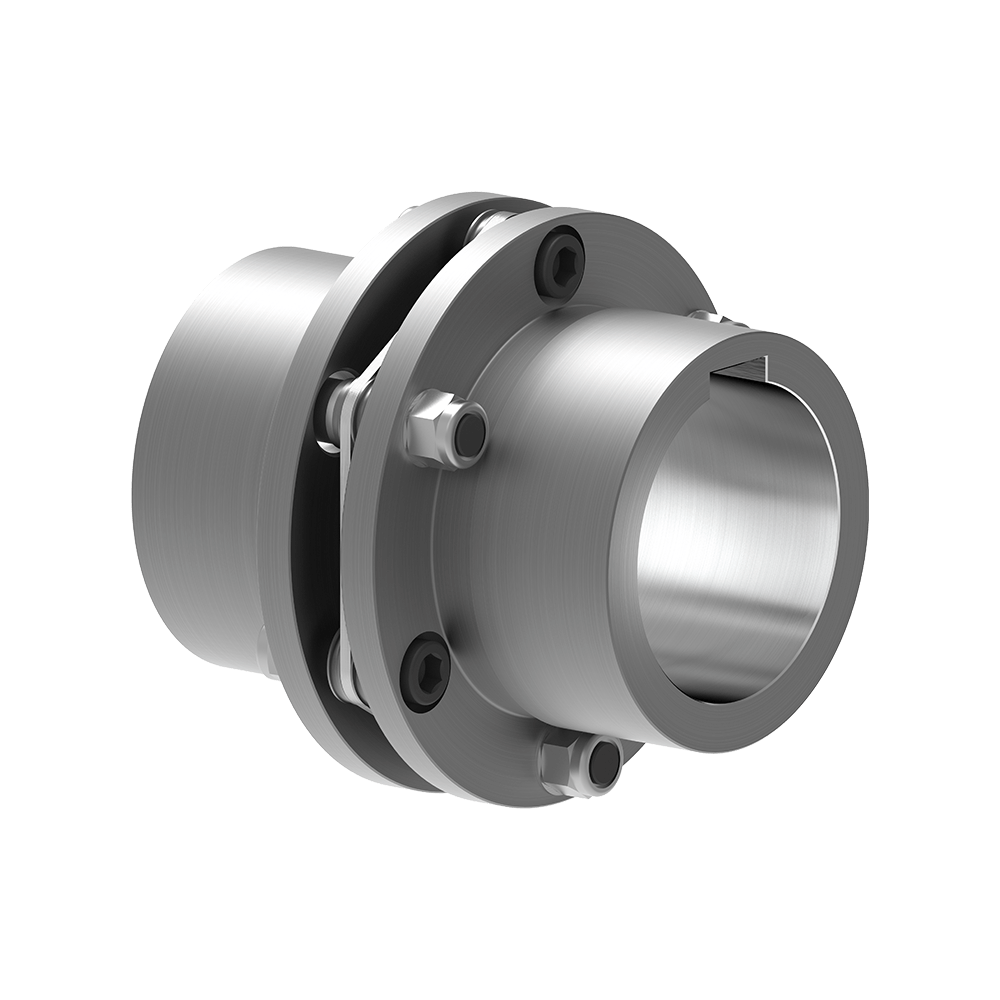

HZPT – Your Trusted Provider of Disc Couplings

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise specializing in the research, development, production, and international trade of coupling products. With a focus on innovation and customer satisfaction, HZPT has established itself as a reliable and respected provider of disc couplings.

Our disc coupling product line offers a wide range of advantages:

1. High-quality materials: We use premium-grade materials in the manufacturing of our disc couplings to ensure durability and longevity.

2. Precision engineering: Our disc couplings are meticulously engineered to deliver exceptional performance, high torque transmission, and reliable misalignment compensation.

3. Customization options: We understand that each application has unique requirements. That’s why we offer customization options to tailor our disc couplings to your specific needs.

4. Rigorous testing and quality control: All our disc couplings undergo rigorous testing and quality control measures to ensure they meet the highest industry standards.

5. Worldwide reputation: HZPT has built a strong reputation for delivering reliable and efficient disc couplings to customers around the world. Our commitment to customer satisfaction and product excellence sets us apart from the competition.

Whether you are in the power generation, petrochemical, mining, marine, or steel industry, HZPT has the expertise and product range to meet your disc coupling needs. Partner with us and experience the benefits of our high-quality products, exceptional customer service, and technical support.

Contact us today to discuss your disc coupling requirements and explore how HZPT can help enhance your operations.