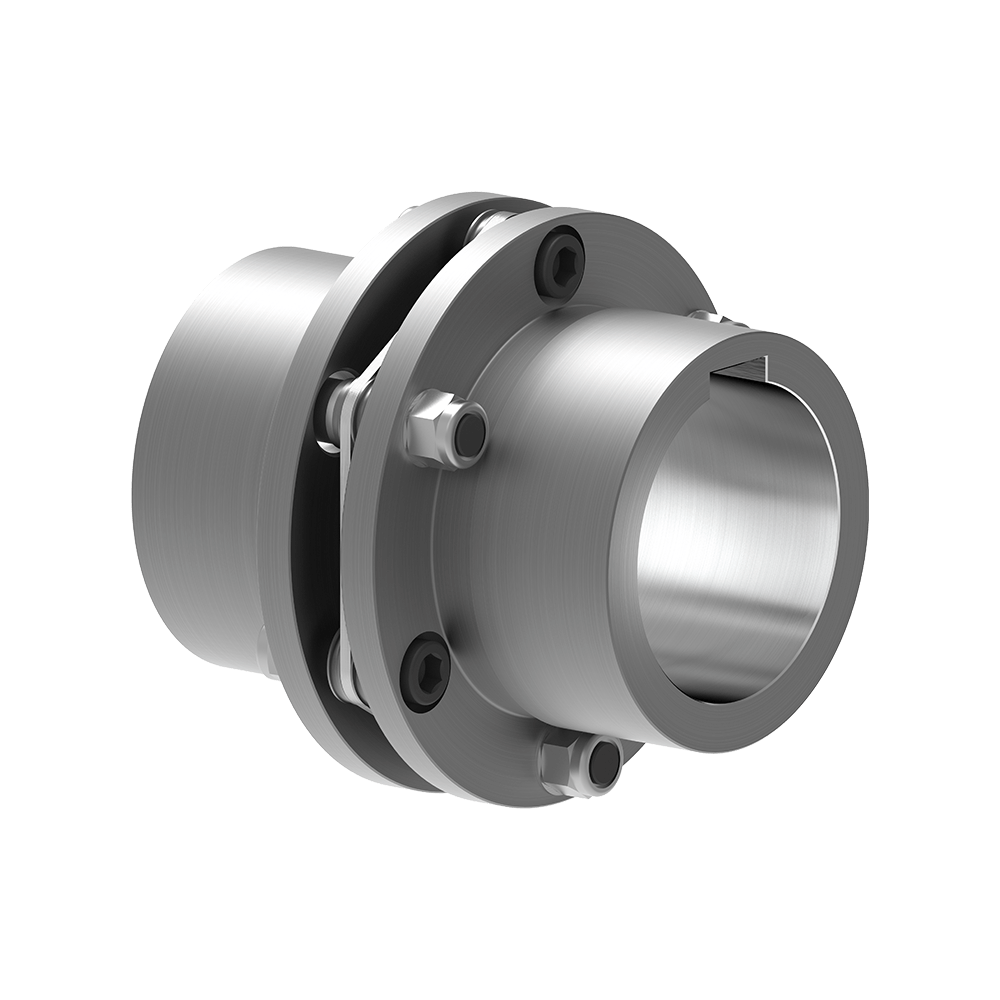

Spring Disc Coupling

Introduction

Disc coupling is a type of flexible coupling commonly used in mechanical power transmission systems. It consists of two parallel metal discs connected by a series of high-strength bolts. The discs are designed to flex and absorb misalignments between the connected shafts while transmitting torque. The spring element in the disc coupling provides flexibility, allowing for angular, axial, and parallel misalignments.

Advantages of Disc Coupling

1. High Torque Capacity: The design of the disc coupling allows it to transmit high torque loads efficiently, making it suitable for heavy-duty applications.

2. Misalignment Compensation: Disc couplings can accommodate angular, axial, and parallel misalignments, ensuring smooth operation and reducing stress on connected equipment.

3. Torsional Stiffness: The stiffness of the disc coupling helps maintain accurate positioning of the connected shafts, which is crucial for precision applications.

4. Zero Backlash: The bolted connection between the discs ensures no backlash during operation, resulting in precise torque transmission.

5. Maintenance-Free: Disc couplings require minimal maintenance due to their simple design and durable materials.

Choosing and Customizing a Disc Coupling

When selecting or customizing a disc coupling, several parameters and practical conditions need to be considered:

1. Torque Capacity: Determine the required torque capacity based on the power transmission requirements and the connected equipment’s torque characteristics.

2. Speed and Misalignment: Consider the operating speed and expected misalignments (angular, axial, and parallel) to choose a disc coupling with the appropriate flexibility and stiffness.

3. Environmental Conditions: Assess the operating environment for factors like temperature, humidity, and presence of corrosive substances to select a disc coupling with suitable materials and coatings.

4. Size and Space Limitations: Take into account the available space for installation and the size limitations imposed by the system’s design.

5. Mounting and Connection: Consider the connection method between the coupling and the shafts, ensuring compatibility and ease of installation.

Does Disc Coupling Need Lubrication?

Unlike some other types of couplings, disc couplings generally do not require lubrication. The metal discs and bolts are designed to operate with minimal friction, reducing the need for lubrication. However, specific application requirements or environmental factors may necessitate lubrication in certain cases. It is recommended to consult the manufacturer or refer to the product documentation for lubrication guidelines.

What are Disc Couplings Used For?

Disc couplings are widely used in various industries and applications, including:

1. Power Transmission Systems: Disc couplings are utilized to connect rotating shafts in machinery such as pumps, compressors, generators, and turbines.

2. Industrial Automation: They are employed in precision motion control systems, robotics, CNC machines, and other automation equipment.

3. Paper and Printing: Disc couplings are used in printing presses, paper mills, and other paper handling equipment where accurate shaft alignment is critical.

4. Oil and Gas: They find application in oil rigs, pipelines, and refineries due to their ability to handle high torque, misalignments, and harsh environmental conditions.

5. Mining and Heavy Machinery: Disc couplings are used in mining equipment, crushers, conveyors, and heavy-duty machinery requiring reliable power transmission.

Why Choose HZPT for Disc Couplings?

HZPT, located in Hangzhou, Zhejiang Province, is a modern enterprise specializing in the research, development, production, and international trade of coupling products. Here are five reasons to choose our disc couplings:

1. High-Quality Manufacturing: We have a complete and scientific quality management system, along with our own technical development and testing department. Our products are certified with CQC, ISO, CE, and other quality standards.

2. Wide Range of Products: We offer a comprehensive range of disc couplings, including drum-shaped couplings, pin coupling, serpentine spring couplings, universal couplings, star-shaped couplings, expansion couplings, diaphragm couplings, and tire couplings.

3. Customization Options: We can provide tailored solutions to suit specific application requirements, including custom designs, materials, and coatings.

4. Global Presence: Our business spans across Asia, Europe, Africa, and North America, positioning us as an international group with global influence.

5. Customer-Focused Approach: We prioritize customer satisfaction and provide excellent sales services and technical support. With a philosophy of “people-oriented and customer-first,” we strive for mutual development through sincere cooperation with our clients.

For more information about our disc couplings and other products, please visit our website or contact us directly.