Introduction to TB Woods Disc Coupling

1. Overview of TB Woods Disc Coupling

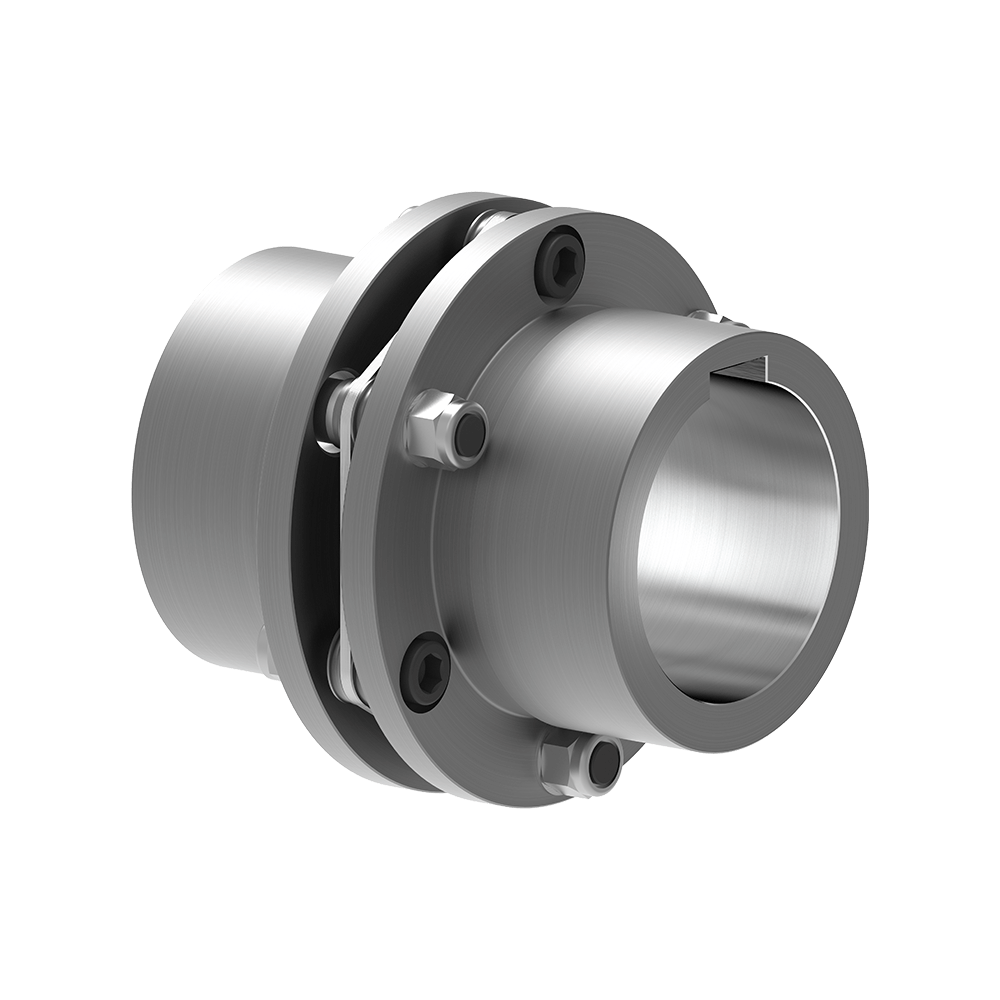

TB Woods disc coupling is a type of flexible coupling used to transmit torque between two shafts. It consists of two metal hubs and a series of parallel metal discs, also known as flex elements or packs. These discs are bolted between the hubs, allowing for misalignment and torsional flexibility.

2. Advantages of TB Woods Disc Coupling

TB Woods disc coupling offers several advantages over other types of couplings:

– High Torque Capacity: The design of the disc coupling allows for efficient torque transmission, making it suitable for heavy-duty applications.

– Torsional Flexibility: The flex elements in the disc coupling can accommodate angular, axial, and parallel misalignments, reducing stress on the connected equipment.

– Vibration Damping: The parallel discs in the coupling act as damping elements, absorbing vibrations and reducing the risk of damage to the connected machinery.

– Easy Installation and Maintenance: The modular design of TB Woods disc couplings allows for quick and simple installation. They also require minimal maintenance, resulting in reduced downtime and increased productivity.

– Compact Size: Disc couplings have a compact design, making them suitable for applications where space is limited.

3. Selection and Customization of Disc Couplings

When selecting or customizing a disc coupling, it is important to consider the following parameters and practical conditions:

– Torque Requirements: Determine the maximum torque that the coupling needs to transmit.

– Speed and RPM: Consider the operating speed and RPM range to ensure the coupling can handle the required rotational speed.

– Shaft Sizes: Match the coupling’s hub size to the shaft sizes of the connected equipment.

– Misalignment Compensation: Evaluate the expected misalignment in terms of angular, axial, and parallel misalignments to select the appropriate disc coupling.

– Environmental Factors: Take into account the operating environment, such as temperature, humidity, and presence of corrosive substances, to choose a suitable material for the coupling.

4. Does Disc Coupling Need Lubrication?

TB Woods disc couplings are designed to operate without the need for lubrication. The metal discs and hubs are typically made from materials with low friction coefficients, allowing for smooth operation without the use of additional lubricants. This feature reduces maintenance requirements and ensures reliable performance.

What are Disc Couplings Used for?

Disc couplings are commonly used in various industrial applications, including:

– Power Transmission: Disc couplings are used to connect drive systems in machinery, such as pumps, compressors, generators, and turbines.

– Motion Control: Disc couplings enable precise motion control in applications like robotics, CNC machines, and printing presses.

– Automotive Industry: Disc couplings are used in automotive powertrain systems to transmit torque between the engine and the drivetrain.

– Marine Applications: Disc couplings are used in marine propulsion systems to transmit torque from the engine to the propeller.

– Oil and Gas Industry: Disc couplings are utilized in oil and gas equipment, such as pumps, compressors, and turbines.

TB Woods – Your Reliable Disc Coupling Manufacturer

HZPT, located in Hangzhou, Zhejiang province, is a modern enterprise specializing in the research, development, production, and international trade of coupling products. We offer a wide range of high-quality disc couplings, including TB Woods disc couplings.

Our company is committed to providing excellent customer service and technical support. We have a complete and scientific quality management system, as well as our own technology development and testing department. With certifications such as CQC, ISO, and CE, we ensure the reliability and performance of our products.

Why choose TB Woods disc couplings from HZPT:

1. Superior Torque Transmission: Our disc couplings are designed to handle high torque loads, ensuring efficient power transmission.

2. Flexibility and Misalignment Compensation: The parallel disc design provides excellent misalignment compensation, reducing wear and tear on connected equipment.

3. Vibration Damping and Noise Reduction: Our disc couplings have damping properties, minimizing vibrations and noise during operation, resulting in smoother and quieter machinery.

4. Easy Installation and Maintenance: The modular design of our disc couplings allows for easy installation and minimal maintenance requirements, saving time and reducing downtime.

5. Customization Options: We offer customization services to meet specific requirements, such as different sizes, materials, and torque capacities.

With over [insert number] years of experience in the coupling industry, HZPT is your reliable partner for all your disc coupling needs. Contact us today to discuss your requirements and experience the quality and performance of TB Woods disc couplings.

How to Choose or Customize the Right Disc Coupling

When selecting or customizing a disc coupling for your specific application, consider the following factors:

1. Torque Capacity: Determine the maximum torque that the coupling needs to transmit. This will ensure that the selected coupling can handle the required load.

2. Speed and RPM Range: Consider the operating speed and RPM range to ensure that the coupling can handle the rotational speed without any issues.

3. Shaft Sizes and Fit: Match the coupling’s hub size to the shaft sizes of the connected equipment. Ensure a proper fit to avoid any misalignment or slippage.

4. Environmental Conditions: Take into account the operating environment, including temperature, humidity, and any potential exposure to corrosive substances. Choose a disc coupling with suitable materials that can withstand these conditions.

5. Installation Space and Design: Consider the available space for installation and any design constraints. Choose a disc coupling that fits within the given space and aligns with the overall system design.

Does Disc Coupling Need Lubrication?

No, TB Woods disc couplings do not require lubrication. The design of the coupling, with its metal discs and hubs, allows for smooth operation without the need for additional lubricants. This reduces maintenance requirements and ensures reliable performance.

HZPT, located in Hangzhou, Zhejiang province, is a modern enterprise specializing in the research, development, production, and international trade of coupling products. We offer a wide range of high-quality disc couplings, including TB Woods disc couplings. Our company is committed to providing excellent customer service and technical support. We have a complete and scientific quality management system, as well as our own technology development and testing department. With certifications such as CQC, ISO, and CE, we ensure the reliability and performance of our products.

By choosing TB Woods disc couplings from HZPT, you can benefit from the following advantages:

1. High-Quality Manufacturing: Our disc couplings are manufactured using advanced technologies and high-quality materials, ensuring their durability and longevity.

2. Customization Options: We offer customization services to meet specific requirements, including different sizes, materials, and torque capacities. Our engineering team will work closely with you to design and manufacture the perfect disc coupling for your application.

3. Reliable Performance: TB Woods disc couplings are designed to deliver reliable performance even in demanding environments. They can withstand high torque loads and provide excellent misalignment compensation.

4. Application Versatility: Our disc couplings are suitable for a wide range of applications, including power transmission, motion control, automotive, marine, and oil and gas industries.

5. Excellent Customer Support: We provide comprehensive sales support and technical assistance to ensure that you have the right disc coupling for your needs. Our team is dedicated to delivering exceptional service and ensuring customer satisfaction.

Contact HZPT today to learn more about our TB Woods disc couplings and how they can enhance the performance and reliability of your machinery. Trust in our expertise and experience to provide you with the best coupling solutions for your specific needs.