Product Description

Product Description

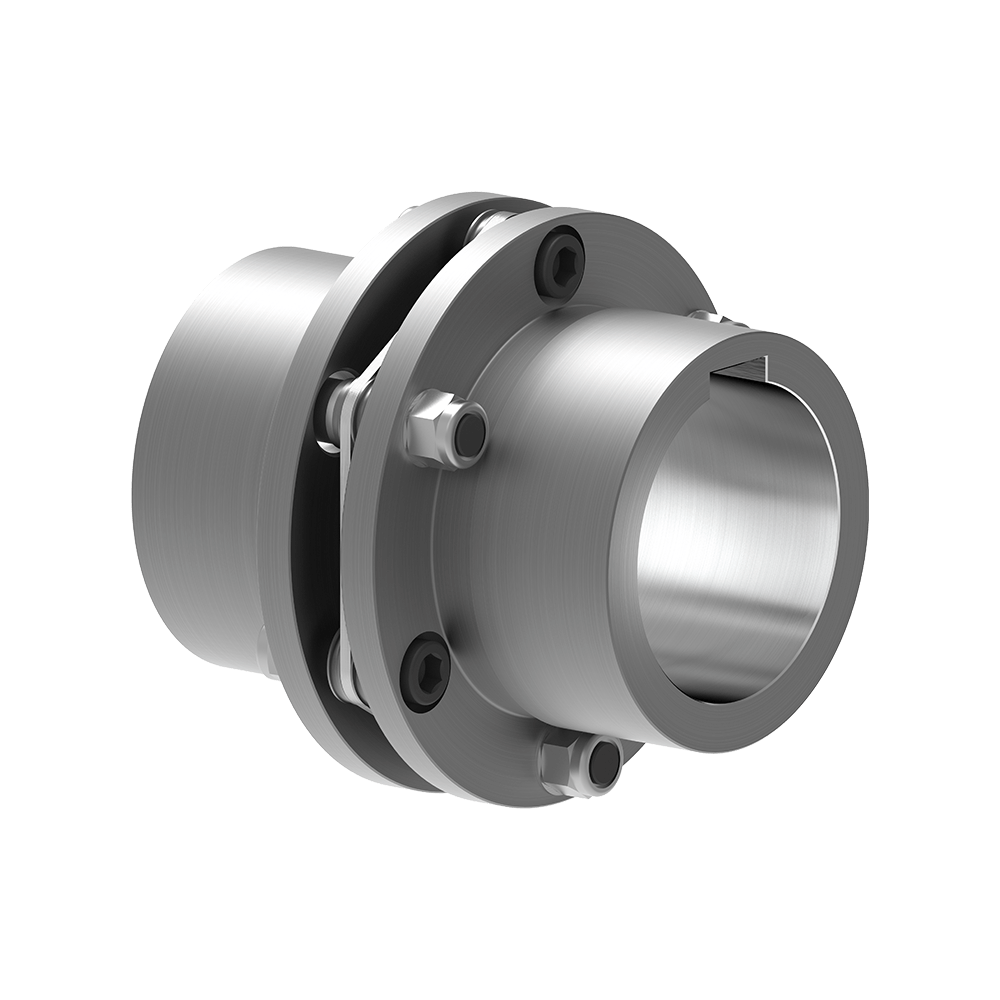

A coupling is a mechanical element part that connects 2 shafts together to accurately transmit the power from the drive side to the driven side while absorbing the mounting error (misalignment), etc. of the 2 shafts.

Packaging & Shipping

Our Advantages

1. We have over 10 years’ experience.

2. OEM or Non-Standard Bearings: Any requirement for Non-standard bearings is easily fulfilled by us due to our vast knowledge and links in the industry.

3. After Sales Service and Technical Assistance: Our company provides after-sales service and technical assistance as per the customer’s requirements and needs.

4. Quick Delivery: Our company provides just-in-time delivery with our streamlined supply chain.

5.We attend promptly to any customer questions. We believe that if our customers are satisfied then it proves our worth. Our customers are always given quick support.

Please contact us immediately if you have any questions.

Related Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Materials Used in Manufacturing Disc Couplings

Disc couplings are typically constructed using a combination of high-quality materials that contribute to their durability, strength, and performance. Some commonly used materials include:

- Stainless Steel: Stainless steel is a popular choice due to its corrosion resistance and high strength-to-weight ratio. It ensures longevity and can withstand harsh environments.

- Aluminum: Aluminum is known for its lightweight properties and is often used in applications where weight reduction is essential while maintaining reasonable strength.

- Steel: Carbon or alloy steel is chosen for its robustness and ability to handle high torque loads and harsh operating conditions.

- Bronze or Brass: These materials can be used in specific applications where electrical conductivity is a concern, or when friction and wear properties are important.

The selection of materials depends on factors such as the coupling’s intended application, torque requirements, environmental conditions, and the desired balance between strength, weight, and resistance to wear and corrosion.

Unique Construction of Disc Couplings for Vibration Dampening and Resonance Control

The distinctive construction of disc couplings plays a vital role in their ability to dampen vibrations and control resonance:

- Flexible Disc Packs: Disc couplings consist of multiple thin metal discs stacked alternately. These discs are connected to the hub and spacer, creating a flexible structure that can absorb and dissipate vibrations.

- Radial Compliance: The flexible discs allow for radial compliance, enabling the coupling to absorb misalignments and shocks, which helps prevent the transmission of vibrations.

- Torsional Flexibility: The flexible nature of the disc packs provides torsional flexibility, allowing the coupling to absorb torsional vibrations and shocks that may arise from the machinery.

- Resonance Damping: The design of disc couplings helps dampen resonant frequencies. The unique construction disperses energy across the flexible elements, reducing the risk of resonant vibration buildup.

- Material Selection: The choice of materials for the discs plays a role in controlling resonance. The right combination of material properties can help mitigate the effects of resonance.

By efficiently absorbing and dissipating vibrations and controlling resonance, disc couplings contribute to smoother operation, reduced wear and tear on machinery components, and enhanced overall system performance.

Considerations for Selecting a Disc Coupling for a Specific Application

Choosing the right disc coupling for a particular application involves considering several important factors to ensure optimal performance and reliability:

- Torque Requirements: Determine the maximum and continuous torque requirements of the application. Select a disc coupling that can handle the expected torque without exceeding its rated capacity.

- Misalignment: Evaluate the type and magnitude of misalignment expected in the system, including angular, parallel, and axial misalignment. Choose a disc coupling with the appropriate misalignment capability to accommodate these factors.

- Speed and RPM: Consider the operating speed and rotational speed of the connected shafts. High-speed applications may require disc couplings with balanced design to prevent vibration issues.

- Space Limitations: Evaluate the available space for installing the coupling. Disc couplings are compact and can be suitable for applications with limited space.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, presence of corrosive agents, and exposure to dust or debris. Choose materials and coatings that can withstand the environmental conditions.

- Shaft Sizes: Ensure that the disc coupling’s hub bore sizes match the shaft sizes of the connected equipment.

- Alignment Maintenance: Consider the ease of installation and alignment maintenance. Some disc couplings feature spacer elements that simplify alignment and reduce downtime during maintenance.

- Backlash: Evaluate the backlash or play that the coupling introduces between the shafts. Backlash can affect the accuracy of position and torque transmission in precision applications.

- Dynamic Balancing: For high-speed applications, consider disc couplings that are dynamically balanced to prevent vibration issues that can arise from rotational imbalance.

- Resonance and Damping: Determine if the coupling design includes features to dampen vibrations and reduce the risk of resonance in the system.

- Service Life: Estimate the expected service life based on the application’s duty cycle and requirements. Choose a disc coupling with a suitable service life to avoid frequent replacements.

- Cost and Value: Compare the cost of the disc coupling with its features, performance benefits, and expected lifespan. Choose a coupling that provides the best value for your specific application.

By carefully considering these factors, you can select a disc coupling that meets the unique requirements of your machinery system and ensures reliable operation.

editor by CX 2024-04-22